What is Screen Printing Machine?

A screen printing machine is a device that uses a mesh screen to transfer ink onto a substrate (such cloth, paper, or plastic). A stencil is used to block out a design or image on the screen, and a squeegee is used to push ink through the exposed regions of the screen. Machines for screen printing can be automatic, semi-automatic, or manual.

Machines for manual screen printing are the most basic and least expensive. They are manually operated; the operator loads the substrate into the device, lowers the screen, uses a squeegee to apply ink, and then raises the screen. Small print runs and hobbyists usually use manual screen printing machines.

Table of Contents

Although they are more advanced than manual equipment, semi-automatic screen printers are still reasonably priced. They have features like an automatic platen loader and a pneumatic squeegee that automate the printing process. Medium to large print runs are usually handled by semi-automatic screen printers.

Although they are the priciest kind of equipment, automatic screen printers are also the most effective. They load the substrate, lower the screen, apply the ink, raise the screen, and unload the substrate—the whole printing process is automated. Large print runs are usually produced by automatic screen printers.

Advantages of screen printing equipment:

Versatility: A wide range of substrates, such as cloth, paper, plastic, wood, and metal, can be printed on by screen printing equipment.

Durability: Screen-printed pictures are incredibly resilient and can tolerate frequent washings and abrasions.

Opacity: Even on dark-colored substrates, screen printing is capable of producing extremely opaque pictures.

Affordability: Screen printing devices, particularly manual and semi-automatic models, are reasonably priced.

10 Screen printing machines features and user reviews:

1. Vastex V-2000HD Series II:

- Features: High-quality construction, micro-registration system, multiple color stations.

- Micro-Registration System

- Multiple Color Stations

- Adjustable Platens

- Sturdy Construction

- Versatility

- User-Friendly Design

- Quick-Release Pallet System

2. Ryonet Silver Press:

- Features: Affordable entry-level option, adjustable and sturdy design.

- Sturdy Construction

- Adjustable Pallets

- Spring-Loaded Pallet Arms

- Easy Setup

- Single Station Design

- Affordability

- Compact Design

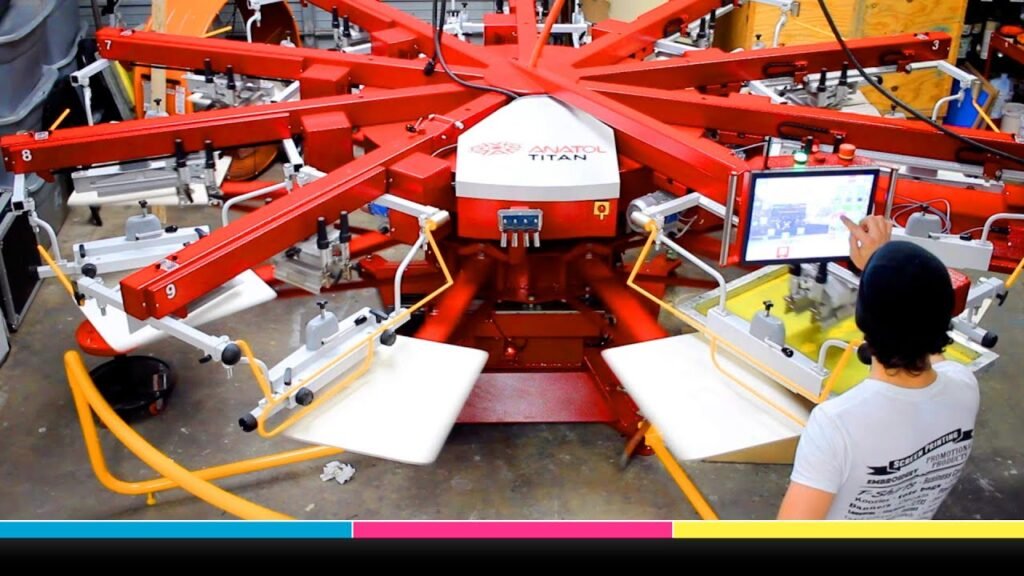

3. Anatol Titan:

- Features: High-speed production, automatic press with various configurations.

- Automatic Press

- High-Speed Production

- Multiple Print Heads and Stations

- Touchscreen Control Panel

- Precision Registration System

- Independent Print and Index Speeds

- Adjustable Pallets

- Durable Construction

- Quick-Release Pallet System

4. M&R Diamondback Series:

- Features: High-speed, automatic press with multiple print heads, touchscreen control.

- Automatic Press

- High-Speed Production

- Multiple Print Heads and Stations

- Touchscreen Control Panel

- Precision Registration System

- Independent Print and Index Speeds

- Adjustable Pallets

- Durable Construction

- Quick-Release Pallet System

5. Vevor Screen Printing Machine:

- Features: Entry-level manual press, adjustable height and printing parameters.

- Automatic Press

- High-Speed Production

- Multiple Print Heads and Stations

- Touchscreen Control Panel

- Precision Registration System

- Independent Print and Index Speeds

- Adjustable Pallets

- Durable Construction

- Quick-Release Pallet System

6. Riley Hopkins 250 Press:

- Features: Entry to mid-level manual press, robust construction, various configurations.

- Sturdy Construction

- Adjustable Pallets

- Micro-Registration System

- User-Friendly Design

- Multiple Color Stations

- Quick-Release Pallet System

- Compact Design

7. Workhorse Odyssey Manual Press:

- Features: Durable and affordable manual press, micro-registration system.

- Sturdy Construction

- Adjustable Pallets

- Micro-Registration System

- User-Friendly Design

- Multiple Color Stations

- Quick-Release Pallet System

- Compact Design

- Durable Platens

- Off-Contact Adjustment

8. M&R Sportsman EX Automatic Press:

- Features: High-speed automatic press, multiple print heads, touchscreen control.

- Automatic Press

- High-Speed Production

- Multiple Print Heads and Stations

- Touchscreen Control Panel

- Precision Registration System

- Adjustable Pallets

- Quick-Release Pallet System

- Durable Construction

9. Anajet mPower i-series:

- Features: Direct-to-Garment (DTG) printer with advanced features for apparel printing.

- Direct-to-Garment Printing

- High-Resolution Printing

- Multiple Color Channels

- User-Friendly Interface

- Garment Platen System

- Wet Cap Maintenance System

- White Ink Printing

- Fast Printing Speeds

- Ink Cartridge System

- Optional Heat Press Integration

10. Lawson Mini-Trooper:

- Features: Compact automatic press, ideal for smaller shops, touchscreen control.

- Compact Design

- User-Friendly Operation

- Adjustable Pallets

- Single Station Design

- Micro-Registration System

- Quick-Release Pallet System

- Durable Construction

- Economical Entry-Level Option

- Compatibility with Lawson Dryers

- Optional Accessories

Hypothetical Features:

1. Automatic vs. Manual Operation:

- Feature: Some machines are fully automatic, while others are manual. Automatic machines are suitable for high-volume production.

- User Review: “The automatic functionality saved us a lot of time, especially for large orders. Simple setup for manual use as well.”

2. Color Station Configuration:

- Feature: Machines come with different color station configurations, allowing for multi-color printing.

- User Review: “The 6-color configuration is perfect for our diverse designs. Registration is spot-on.”

3. Micro-Registration System:

- Feature: Precision micro-registration system for accurate alignment of screens.

- User Review: “Micro-registration made a huge difference in achieving fine details. Prints are consistently sharp.”

4. Touchscreen Control Panel:

- Feature: Touchscreen interface for easy navigation and control.

- User Review: “Intuitive touchscreen control makes it easy for our operators. No steep learning curve.”

5. Adjustable Pallets:

- Feature: Pallets that can be adjusted for different garment sizes and types.

- User Review: “Versatile pallet adjustments make it easy to handle a variety of garments. Saved us from buying multiple machines.”

6. Printing Speed:

- Feature: Varying printing speeds to accommodate different production requirements.

- User Review: “High-speed printing is a game-changer for meeting tight deadlines. Very impressed with the efficiency.”

7. Durability and Construction:

- Feature: Robust construction for durability and stability during the printing process.

- User Review: “Solid build quality. This machine has been running smoothly for months without any issues.”

8. Quick-Release Pallet System:

- Feature: Quick-release system for efficient pallet changes.

- User Review: “The quick-release feature has increased our productivity. Changing pallets is a breeze.”

9. Direct-to-Garment Printing (DTG):

- Feature: DTG capability for direct printing on garments.

- User Review: “DTG feature gives us the flexibility to offer full-color prints directly on garments. Customers love the quality.”

10. User-Friendly Design:

- Feature: Overall user-friendly design for easy setup and operation.

- User Review: “Even our new hires quickly adapted to using the machine. Well-designed and user-friendly.”

Conclusion:

In conclusion, screen printing machines play a crucial role in the printing industry, offering a variety of features to meet the diverse needs of businesses and individuals. Whether it’s manual presses like the Ryonet Silver Press or automatic presses like the M&R Diamondback Series, these machines contribute to efficient and high-quality printing processes. The choice of a screen printing machine depends on factors such as the scale of production, type of printing, and budget constraints.

For direct-to-garment (DTG) printing, models like the AnaJet mPower i-series provide specialized capabilities, including high-resolution printing and the ability to print directly onto garments.

Similarly, compact and versatile machines like the Lawson Mini-Trooper cater to smaller-scale operations, offering user-friendly features and a space-efficient design.

It’s essential for individuals and businesses to conduct thorough research, consider their specific requirements, and stay updated on the latest advancements in screen printing technology. Consulting with industry experts, reading user reviews, and exploring manufacturer specifications are valuable steps in making informed decisions when selecting a screen printing machine. Ultimately, the right choice of a screen printing machine contributes to enhanced productivity, print quality, and overall success in the printing business. More details

Leave A Comment